charpy impact test are used to help determine a metals:|charpy impact testing procedure : purchaser Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its . 5 de fev. de 2024 · Pais de Mavie, Neymar e Bruna Biancardi terminaram relacionamento no ano passado, poucos meses após o jogador se transferir para o Al-Hilal. Em junho, o .

{plog:ftitle_list}

3 dias atrás · Dados do Ministério da Saúde mostram que a média móvel de casos de covid-19 do Brasil está em alta desde a segunda semana do ano, com 80% mais casos do que na mesma época de 2023.

charpy impact testing procedure

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .

The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be used as an economical quality .

The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .

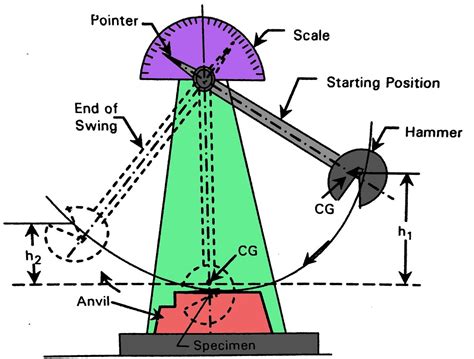

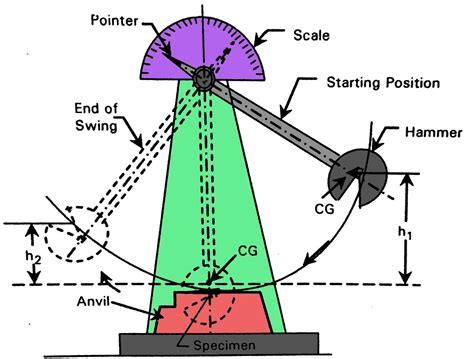

The Charpy impact test, also referred to as Charpy v-notch test, is a materials testing method used to determine the impact strength of materials using a pendulum impact tester.The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure . Charpy testing is a method for determining the relative impact strength of metals. It is also known as the Charpy V notch test. This testing method was developed in the 1940s by S.B. Russell and G. Charpy.

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact .

Study with Quizlet and memorize flashcards containing terms like rockwell hardness test measures:, charpy impact tests are used to help determine a metals, creep and more. . charpy impact tests are used to help determine a . Today, that method, with some upgrades and refinements, remains the standard test used worldwide to judge the impact resistance of metals used in bridge construction, high-pressure boilers, ocean ships, armor .

.the right impact test equipment for standard-compliant testing! Impact testers help determine the failure behavior of materials or components under rapid loads and changing temperatures. Because many materials used for a number of . Charpy impact test is a comparative style test used to define a material’s impact strength. Learn more about it here. . Performing Charpy impact tests on 3D printed samples can help engineers determine the impact strength of various 3D printing materials, especially considering that some technologies print parts with anisotropic properties . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . The Charpy Test. While most commonly used on metals, it is also used on polymers, ceramics and composites. The Charpy test is most .The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

The Charpy impact test, also known as the Charpy V-notch impact test, measures the energy a material absorbs when it fractures under an impact load. A pendulum in a Charpy impact test machine is released to strike a notched specimen, and the amount of energy absorbed during the break is calculated.This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .

charpy impact testing methods

To determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be : Charpy Impact Testing, also known as the “Charpy V-notch test,” is a standardized test method used to determine the impact toughness of materials, particularly metals. It assesses a material's ability to absorb energy during fracture when subjected to a sudden impact. What Does Charpy Impact Test Mean? A Charpy impact test is a test method that is used to determine the toughness of a material. Once machined, a specimen of the material being tested is loaded into a Charpy impact test machine. The amount of force required to fracture the material with a swinging pendulum is used to calculate the toughness.The Charpy impact test is used to determine the sensitivity of a metal's impact strength to changes in temperature. True. . The Charpy impact test is used to determine the sensitivity of a metal's impact strength to changes in temperature. Choose matching definition. True. False. . Help center; Sign up; Honor code; Community guidelines .

Westmoreland Mechanical Testing & Research is most trusted name for testing metallic materials and their ability to resist often impact to help determine service life of a part. WMT&R has the capability of performing a variety of impact tests, including Charpy , IZOD, Instrumental, Drop-Weight and Dynamic Tear Testing .”

Impact Toughness Testing of Metals. satyendra; December 7, 2016; . There are three normally used standard Charpy impact test samples, which are similar except for the notch. . Extensive efforts have been made to help determine the dynamic fracture toughness over a range of behaviour in linear-elastic, elastic-plastic, and fully plastic .Charpy Impact testing is used in studying material toughness and most importantly it indicates a material ability to absorb energy and plastically deform without fracturing. In this study, three stainless steel specimens at different . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness . The Charpy impact test is one of the most widely used techniques for evaluating the impact toughness of metallic materials. This test is based on measuring the energy absorbed by a material during fracture caused by a sudden impact, simulating real stress conditions that could cause a metal component to fracture.

A: The Charpy impact test can be used on a variety of materials, including metals, polymers, and plastics. This flexibility makes it a widely used impact test for evaluating material properties such as ductility and brittleness. Q: What are the main components of a Charpy pendulum impact testing machine?on improving the use of statistics in Charpy measurements. In 2008, NIST published a new Recommended Practice Guide on uncertainty analysis for Charpy tests (Computing Uncertainty for Charpy Impact Machine Test Results), that offers users a full explanation of the uncertainty associated with the NIST reference specimens

The Charpy impact test is a standardized test used to determine the toughness of materials by measuring the amount of energy absorbed during fracture. This test is particularly important for assessing a material's ability to withstand sudden impacts or shocks, which is critical in applications involving fatigue and impact loading. It involves striking a notched specimen with . One of the most common destructive tests used to determine mechanical properties is the tensile test. This test is used to provide information about the tensile strength, yield strength, and ductility of the primary metals and metal alloys. . The Charpy impact test, also commonly referred to as the Charpy V-notch test by material scientists .Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).

Our discussion will cover the different types of impact testing, the necessary equipment, and the valuable data these tests provide. Impact Testing – Charpy and Izod Tests. The impact testing method is pivotal for determining a material’s ductile-to-brittle transition temperature and its ability to resist deformation due to impact loads.

The Charpy impact test is highly useful for determining the operational parameters of these materials. The Charpy test can also be used to evaluate structural conditions and heat treatments of materials such as ferritic steels. Furthermore, this test can be used to determine the impact of aging in structural materials.

Impact testing measures the material’s ability to absorb energy when fractured at high velocity. This gives an indication of the ‘toughness’ of the metal and two methods are usually employed for impact testing, Charpy or Izod. Tensile testing Tensile Testing, or Tension Testing, is used to determine the behaviour of the metal when it is .The Class D Metals Impact Tester is a Single column impact testing system designed for Charpy Impact testing according to ASTM E23, ISO 148 and EN10045 industry standards. The Class D has has two popular models with peak capacities of 450J and 750J with optional pendulums for 150J, 300J, 450J and 600J.Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of metals. It is a standardised high strain-rate test that can measure the amount of energy absorbed in a material. . sometimes called „Time-History Analysis‟, is a technique used to determine the dynamic response of a structure under .

Resultado da 1 de jul. de 2023 · 2022. Geral. NÃO RECOMENDADA -- /10 01/07/2023 - 31/12/2023. Reclamações. 20. Respondidas. 8. A empresa se enquadra como Não Recomendada pois não responde a pelo menos 50% das reclamações recebidas no ReclameAQUI. Entenda como calculamos a reputação.

charpy impact test are used to help determine a metals:|charpy impact testing procedure